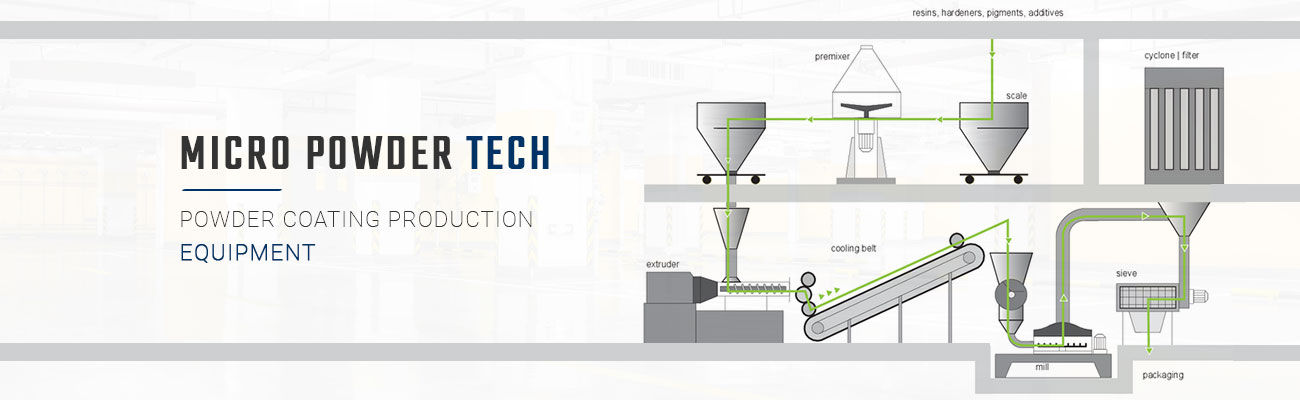

Powder Coating Production Machine

Product Details:

- Product Type Powder Coating Production Machine

- General Use Industrial Powder Coating Application

- Material Mild Steel

- Type Automatic Coating Machine

- Weight (kg) Approx. 1500 kg

- Coating Speed Up to 30 m/min

- Coating Head Single/Double

- Click to View more

Powder Coating Production Machine Price And Quantity

- 1 Set

Powder Coating Production Machine Product Specifications

- 800 mm

- Powder Coating Production Machine

- PLC based with Touch Screen HMI

- Industrial Powder Coating Application

- Manual/Automatic Option

- Industrial Blue/White

- Thermosetting Powder

- Electric Heating

- Mild Steel

- 3200x2100x2200 mm

- Electric

- Approx. 1500 kg

- Fully Automatic

- Epoxy/Polyester Powder

- Automatic

- 15-18 kW

- Yes

- 380V/415V, 50/60Hz

- Up to 800 mm

- Up to 30 m/min

- 800 mm

- High Efficiency, Uniform Coating, Easy Operation

- No

- Automatic

- Single/Double

- Automatic Coating Machine

Powder Coating Production Machine Trade Information

- No

- Contact us for information regarding our sample policy

Product Description

We have gained more than 3 decades of experience in manufacturing, exporting and supplying Powder Coating Plant. This plant is manufactured using optimum quality components and contemporary techniques by our skilled professionals at our advanced production unit. The offered plant is extensively used for powder coating. Apart from this, clients can easily avail this Powder Coating Plant in bulk at competitive prices in various technical specifications.

Features:

- Long functional life

- Less maintenance

- Excellent efficiency

- Power efficient

TWIN SCREW POWDER COATING EXTRUDER

We have installed more than 80% Powder Coating Manufacturing Plants in India. We have an expertise in this field. For the development of high quality products, we have set up a modern laboratory with the latest equipment for manufacturing innovative products. MPT-30PC, MPT-40PC MPT- 45PC & MPT- 55PC TWIN SCREW POWDER COATING EXTRUDER are the most latest developments of our company. Our product is cost-effective and energy efficient. It has high speed as well as the excellent cutting & mixing capability with screw speed 0 - 500 RPM. As compared to other type of machines, our MPT-PC TWIN SCREW EXTRUDER can offer finished products with leveling property, increased glossiness and fullness with the same gloss powder formula and without and any change in screw configuration. This product is made of high quality alloy steel that ensures strong wear resistance and superior hardness. Our product has smooth and balanced transmission.

Standard Features:

-

Very good mixing and dispersing effect. Having short residence time.

-

Economic production cost owing to high output and low power requirements

-

Compact unit, programmable AC speed control drive and automatic temperature digital controller

-

High quality clamshell barrel is open and gives access for maintenance and cleaning operations.

-

Segmented screw components that allow flexibility as well as the maximization of quality.

-

Splinted shaft that has quick release coupling.

-

Volumetric feeders, which have the output capacity of 20 Kg./hr. to 500 Kg./hr.

-

Good steel structure and mounting base

-

Chill knife

-

Good feeding of fine powders and high free volume

-

Economical and reliable

-

Highly wear resistant

Technical Specification :

|

Model |

Screw dia mm |

L/D |

Power kW |

Heating power |

Screw Speed |

Output Kg/Hr |

|

MPT-30PC |

30 |

15:1 |

6.75 |

1.5 |

0-400 |

30-40 |

|

MPT-40PC |

40 |

17.5:1 |

12.5 |

2.2 |

0-450 |

70-100 |

|

MPT-45PC |

45 |

17.5:1 |

16.5 |

3.0 |

0-450 |

150-200 |

|

MPT-55PC |

55 |

17.5:1 |

24.7 |

4.5 |

0-450 |

250-300 |

|

MPT-65PC |

65 |

17.5:1 |

39.7 |

5.5 |

0-450 |

400-500 |

Technical Details (Twin Screw Extruder MPT 45 ):

|

Product/Model |

Twin Screw Extruder MPT-45 PC |

|

|

Capacity |

Kg/h |

150 - 200 |

|

Extruder |

Type |

Twin Screw |

|

Model |

|

MPT-45PC |

|

L/D |

|

17.5:1 |

|

Screw dia |

mm |

45 |

|

Screw speed |

rpm |

0-450 |

|

Main power |

Kw |

18.75 |

|

Drive type |

|

AC frequency drive |

|

Make |

|

Schneider Electric |

|

Heating power |

Kw |

4.8 |

|

Vol. feeder with hopper |

|

|

|

Hopper volume |

Liter |

60 Ltrs. |

|

Power with AC frequency drive |

Kw |

0.37 KW |

|

Capacity |

Kg/h |

20-300 Kg./h |

|

No. of heating/cooling zones |

|

3 zone |

|

Heating Type |

|

Cartridge Heaters |

|

Screw shaft |

|

Hexagonal section hard chrome |

|

Screw elements |

|

Feed screw, Paddle intermeshing |

|

Barrel |

|

Split type opening, Segmented liner insert |

|

Vol. screw feeder |

|

Speed variable screw feeder |

|

Gear box |

|

High efficiency, forced lubrication with cooling arrangement |

|

Control voltage |

V |

420 Volt 3 Phase |

|

CHW flow rate |

Lph |

1400 Ltrs./h |

|

Temperature |

oC |

10 to 12 oC |

|

Controls & Instrumentation |

||

|

PID Control |

|

PID Controlled 2 Nos. |

|

Speed |

|

AC Frequency drive |

|

Temperature |

|

PID Digital Temp. |

|

Display provided in panel |

||

|

|

Motor Speed |

Digital Screw RPM Meter |

|

|

Output Voltage |

415 Volt |

|

|

Current |

AMP Digital Meter |

|

|

Power |

3 Phase Digital indicator, Volt meter |

|

|

Drive Temp |

Frequency drive internal feature |

|

|

Hour counter |

Digital / Analogue |

|

Protections (Electrical and Machine Interlocks) |

||

|

|

Drive temp |

Drive internal protection |

|

|

Motor load |

Drive internal protection |

|

|

Under Voltage |

SPP |

|

|

Earth fault |

SPP |

|

|

Mains supervision |

MCB |

|

|

Phase supervision |

Digital Volt meter, 3 Phase indicator |

Advanced Automation for Precision and Efficiency

The machine operates on a fully automated system driven by PLC controls and an intuitive touch screen HMI interface. This ensures that processes run smoothly, with precise digital adjustment of all parameters, including temperature and speed. Operators can easily manage production settings, reducing manual intervention and improving both productivity and product consistency.

Uniform, Anti-Corrosive Surface Finishing

With a reliable feeding mechanism and advanced digital temperature control, the machine guarantees even distribution of epoxy or polyester powder, producing a high-quality, anti-corrosive finish on all coated surfaces. Its design supports continuous production, making it ideal for high-demand applications and diverse industrial sectors.

Built-In Safety and Easy Maintenance

Safety features such as emergency stop and overload protection are standard, ensuring the machine operates securely during long shifts. Its robust mild steel construction and electric heating system make it durable and maintenance-friendly, enabling efficient operation in demanding industrial settings.

FAQs of Powder Coating Production Machine:

Q: How does the powder coating production machine ensure a uniform finish?

A: The machine utilizes a vibratory hopper or screw feeder to distribute thermosetting powder evenly across the material. Coupled with digital, adjustable temperature control and advanced coating heads (single or double), it achieves a consistently uniform, anti-corrosive finish with every use.Q: What is the typical process for operating this powder coating machine?

A: Operation begins by loading the material onto the unwinder (manual or automatic), after which the vibratory or screw feeder dispenses the powder. The powder is applied while the material moves at up to 30 m/min. The digital PLC system allows for precise parameter adjustments, and the automatic rewinder collects the finished product.Q: Where is this machine most commonly used?

A: This powder coating machine is widely employed in automotive, furniture, appliance manufacturing, and other industrial sectors requiring high-volume, durable, and anti-corrosive coating solutions.Q: What benefits does the fully automatic operation provide?

A: Automated operation reduces the need for manual intervention, minimizing errors and ensuring consistent quality. It also streamlines production, maximizes throughput, and enhances overall efficiency while maintaining safety and ease of use.Q: How is safety maintained during the operation of this machine?

A: The machine is equipped with an emergency stop button and overload protection to safeguard operators and equipment during emergencies. Its low noise levels and secure control system further contribute to a safe working environment.Q: When should the digital temperature control be adjusted?

A: Digital temperature settings should be adjusted when changing powder types (epoxy versus polyester) or to accommodate different coating thickness requirements. Precise adjustment can be done easily via the touch screen HMI to ensure optimal curing and finish.Q: What makes this machine suitable for industrial applications?

A: With a production capacity of 300-500 kg/hour, high-speed operation, uniform coating capability, rugged construction, and advanced safety and control systems, the machine is optimized for industrial environments where reliability, productivity, and surface quality are paramount.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Powder Coating Machinery' category

|

MICRO POWDER TECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |