Air Classifying Mill Coating Machine

Product Details:

- Product Type Air Classifying Mill Coating Machine

- General Use Powder coating for industrial applications

- Material Stainless Steel

- Weight (kg) Approx. 1500kg

- Coating Speed Adjustable

- Coating Head Single

- Coating Width Varies by configuration

- Click to View more

X

Air Classifying Mill Coating Machine Product Specifications

- Electric

- Standard industrial levels

- Not included

- Yes

- Gray

- Included

- Air Classifying Mill Coating Machine

- Electric

- Single

- Adjustable

- 1 year

- Stainless Steel

- Powder coating for industrial applications

- Powder Coating

- Varies by configuration

- Varies by model

- Yes

- Air classifying for precise coating

- 220-380V (varies)

- PLC

- Approx. 1500kg

Product Description

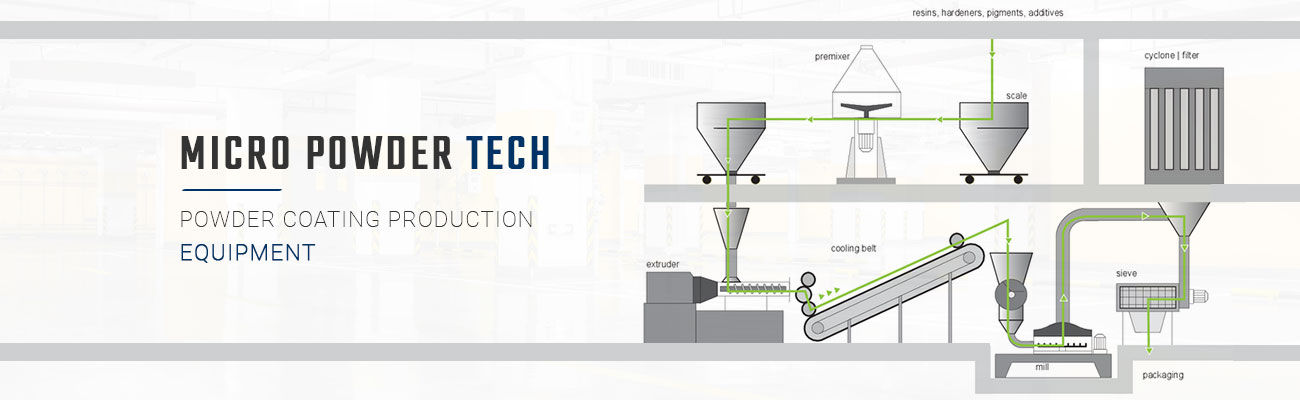

Air Classifying Mill Coating Machine has extensive applications in mineral processing, Resin and Powder Coating production industries. This coating plant consists of user friendly control panel, ergonomic classifier, well lubricated bearings, cages and dynamic or static particle classification section. Designed by adroit professionals, this coating plant deserves praise for is low downtime rate, low operation cost, stable functioning, noise less working mode, low wastage rate and easy installation process. Moreover, its maintenance cost is affordable. We would like to introduce ourselves as a growth oriented exporter and manufacturer of standard grade Air Classifying Mill Coating Machine.

Advanced Powder Coating Technology

With air classifying capabilities, this coating machine delivers uniform and high-quality powder coatings for various industrial products. The integrated heating system enhances curing and finish, while adjustable speed settings provide flexibility for different materials and thickness requirements.

Comprehensive Control and Automation

Utilizing a smart PLC control system, operations are automated and precisely managed. The computerized design ensures efficiency and minimizes human error, making it suitable for both large-scale manufacturing and custom coating jobs.

Durable and Versatile Construction

Built from robust stainless steel, the machine can withstand demanding industrial environments. Its variable dimensions adapt to diverse application needs, while the electric drive and standard voltage compatibility ensure easy installation and operation.

FAQs of Air Classifying Mill Coating Machine:

Q: How does the air classifying feature benefit the powder coating process?

A: The air classifying mechanism enhances coating precision by accurately separating and distributing powder particles, resulting in a more uniform and high-quality finish on coated products.Q: What is the process for adjusting the coating speed on this machine?

A: The coating speed can be modified using the PLC control system, allowing operators to set the desired rate according to material type and specific production requirements.Q: When should the heating system be utilized during coating operations?

A: The heating system should be engaged during the curing phase to ensure the powder is properly bonded and finished, producing a durable and professional coating.Q: Where is this air classifying mill coating machine typically used?

A: This machine is primarily used in industrial manufacturing plants in India that require precise and efficient powder coating for products such as metal components, appliances, and automotive parts.Q: What are the main usage instructions for this coating machine?

A: For optimal results, operators should configure the coating width, set the desired speed, and select appropriate powder material. Regular maintenance and monitoring through the PLC system are recommended for sustained performance.Q: What are the benefits of a computerized and automatic coating system?

A: The computerized and automatic functions streamline operations, reduce manual labor, and improve consistency and accuracy, which translates to higher productivity and better-quality finishes with minimal operator intervention.Q: How does the included warranty support machine owners?

A: The one-year warranty provides protection against manufacturing defects, giving owners peace of mind and assurance of reliable after-sales support from the manufacturer or supplier.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Powder Coating Machinery' category

|

MICRO POWDER TECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |